Manufacturing Metamorphosis: Generative AI and the Automotive Production Revolution

- Aug 23, 2023

- 2 min read

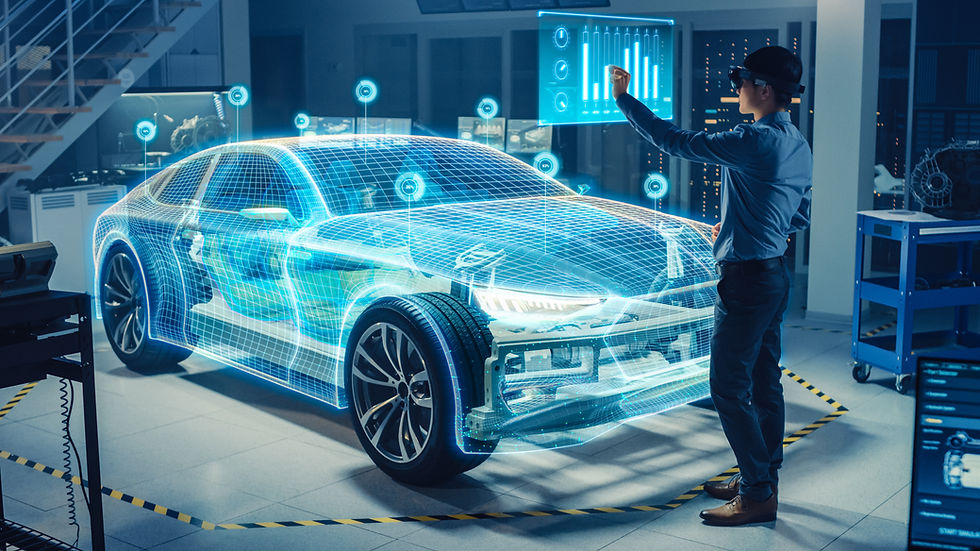

Within the realm of automotive manufacturing, a digital metamorphosis is underway—Generative Artificial Intelligence (AI) is redefining the landscape of production. This article delves into the heart of manufacturing excellence, revealing how the fusion of cutting-edge technology and industrial prowess is reshaping the way we produce, assemble, and ensure quality in the automotive industry. From optimized processes to robotic automation, Generative AI is nurturing a future where every vehicle manufactured embodies precision, innovation, and efficiency.

Introduction: Generative AI's Impact on Automotive Manufacturing

Automotive manufacturing has evolved into a realm empowered by AI. As demand for precision, speed, and quality surges, technology becomes the blueprint for production excellence. Generative AI collaborates with engineers, designers, and production experts, revolutionizing the way we fabricate, assemble, and scrutinize vehicles with meticulous attention to detail.

Process Optimization in Assembly Lines: Orchestrating Efficiency

Assembly lines are a symphony conducted by AI. Generative AI analyzes production data to optimize processes, streamlining assembly and reducing cycle times. This orchestration enhances efficiency and maximizes output without compromising on quality.

Tool and Fixture Design: Crafting Precision Tools

Tools are refined with AI finesse. Generative AI designs fixtures and tools optimized for each manufacturing step. These AI-generated designs improve accuracy, reduce errors, and ensure consistency in production.

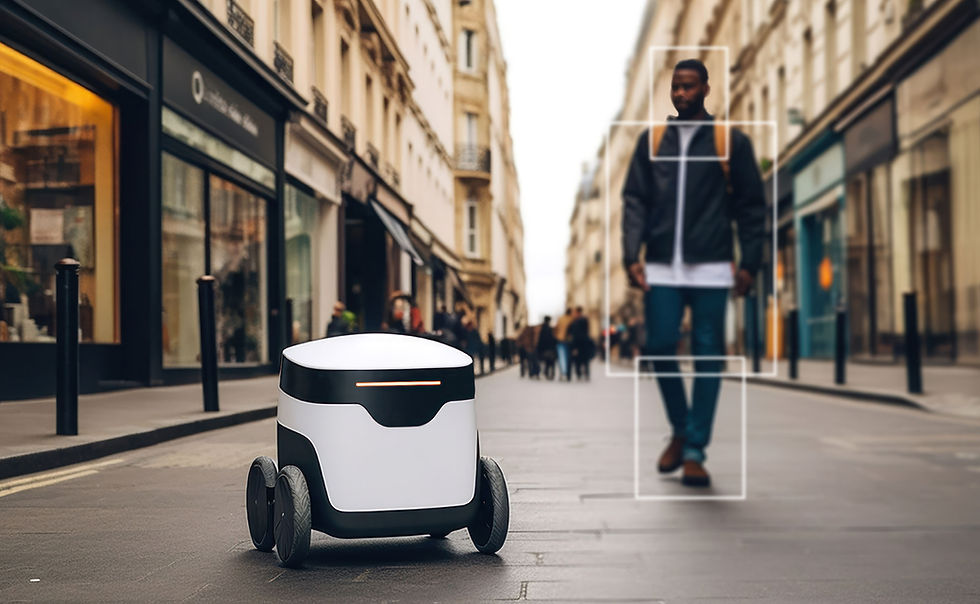

Robotic Path Planning for Automation: Navigating Automation Avenues

Automation is directed by AI prowess. Generative AI maps robotic paths that ensure seamless automation. These optimized paths minimize errors, increase productivity, and make robotic assembly a hallmark of precision.

Quality Control and Defect Detection: Sculpting Perfection

Quality is meticulously monitored with AI's watchful eye. Generative AI analyzes production data to detect defects in real-time. This early intervention ensures that only vehicles meeting stringent quality criteria proceed, elevating brand reputation and customer satisfaction.

Enterprise Technology Solutions: Enabling Manufacturing Transformation

Enterprises play a pivotal role in this transformation. Technology solutions companies integrate Generative AI with manufacturing systems, enhancing data integration and analysis. These partnerships ensure a seamless integration of AI into existing production environments, fostering a harmonious evolution.

Supply Chain Visibility: Enhancing Coordination

Generative AI enriches supply chain visibility. By analyzing data from suppliers and logistics partners, AI-generated insights optimize material flow and distribution. This coordination ensures that production is timely and efficient.

Sustainability Integration: Fostering Eco-Conscious Manufacturing

Generative AI champions sustainability in manufacturing. By analyzing environmental impacts and material usage, AI suggests processes that reduce carbon footprint. This integration ensures that automotive manufacturing aligns with eco-conscious objectives.

Challenges and Ethical Considerations: Guiding AI's Integration

As Generative AI transforms manufacturing, challenges arise. Balancing AI-generated solutions with human expertise, addressing concerns of data security, and ensuring ethical use of AI in decision-making processes are crucial.

Conclusion: Crafting the Future of Automotive Manufacturing

Generative AI's impact on manufacturing is akin to sculpting a masterpiece of precision. As process optimization, tool and fixture design, robotic automation, and quality control converge, they nurture a future where automotive manufacturing transcends its boundaries, yielding vehicles that epitomize innovation, precision, and sustainable progress.

Comments